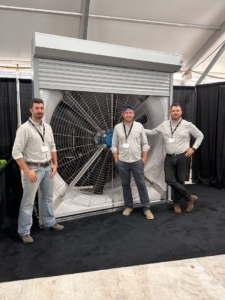

Why a Cyclone Fan?

Our Cyclone fans are purpose built for the Dairy industry and are the highest quality dairy developed fan in the world. We Manufacture everything “in-house” so we oversee everything from design through the manufacturing process. This means we have complete oversight on quality control.